This article covers topics like 5-axis CNC machines, aluminum 7075, polyetheretherketone (PEEK), and Nylon. The ultimate guide will also cover the types of materials you can machine, from basic plastics to more complex metals. Regardless of your experience level, this article will give you the knowledge you need to get started on CNC machining. After reading this article, you’ll be well on your way to being a CNC expert.

5-axis CNC machines

When purchasing a 5 axis CNC machine, there are several factors to consider. Cutting speeds, material, and spindle type are just a few factors to consider. Also consider surface quality, if you need a high degree of tolerance, and the processing power of the CNC control. The higher the processing power, the more features a machine can process in a single setup. And of course, if you need to machine multiple surfaces simultaneously, you’ll need a higher-end model with more axes and more features.

To determine which type of 5-axis CNC machine is best for your business needs, you’ll need to consider the type of work you’ll be doing. High-speed applications require high-speed machining, and 5-axis CNC systems can handle them. These machines also have a higher workpiece-holding capacity. Because they have five axes of motion, they’re suited for parts with large depth-to-width ratios. However, this kind of machine’s broader range of motion can increase chatter and reduce overall accuracy.

Aluminum 7075

If you’re looking for an alloy that will be easy to machine and can withstand high-stress applications, then you’ve probably heard of aluminum 7075. This alloy has excellent machinability and corrosion resistance, but it also exhibits poor cold-forming properties. It is not recommended for welding or soldering, but is used in mold tool manufacturing. It also offers great strength and resistance to atmospheric environments.

It is possible to achieve the best finish by using aluminum as a CNC machining material. Compared to other metals, aluminum has the highest strength and rigidity. Due to this, it is an excellent choice for CNC machining. For rough cuts, you should choose a feed rate of 0.15 to 2.03 mm/rev. For finishing cuts, you can use a feed rate between 0.05 to 0.15 mm/rev. Generally, mineral oils and soluble oil emulsions are appropriate, but remember that these materials have different properties and can stain aluminium.

Polyetheretherketone (PEEK)

If you’re new to CNC machining, you may be wondering about the differences between PEEK and other materials. PEEK is a thermoplastic material that has a melting point of 341 degrees Celsius. Its unique chemical resistance and high melting point allow it to be machined at a high rate while maintaining its structural integrity. Moreover, the material can tolerate continuous high temperatures of up to 260 degrees Celsius without losing its structural integrity. Consequently, it is widely used in various industries, including aerospace, automotive, medical, semiconductor, and chemical.

The material PEEK is a thermoplastic polymer that is suited for a variety of applications. It is lightweight, heat-resistant, chemical-resistant, and anti-magnetic. Its advantages make it ideal for machining parts made of PEEK. While the material’s high melting point can make it hard to machine, it has many benefits. Learn more about PEEK by following the Ultimate Guide to CNC Machining

Nylon

CNC machining is the process of turning unprocessed materials into finished products. Various materials are used for CNC machining. For example, stainless steel is popular because of its corrosion resistance and high strength-to-weight ratio. Other materials include brass, which is not as hard as steel but offers superior electrical conductivity and corrosion resistance. Aluminum alloys are lightweight but remarkably strong and are used extensively in aerospace and automotive craft.

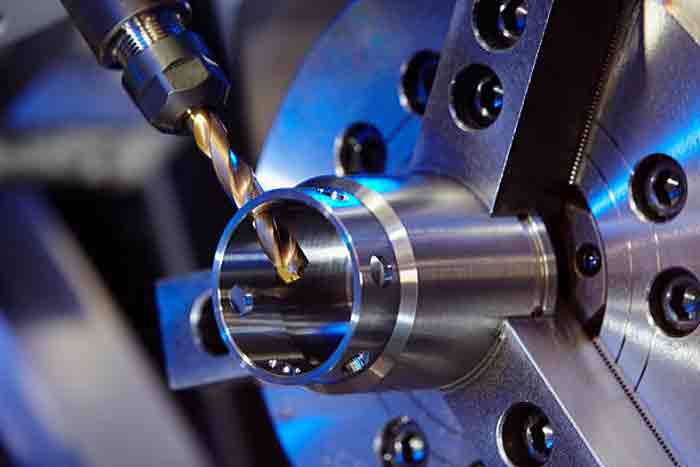

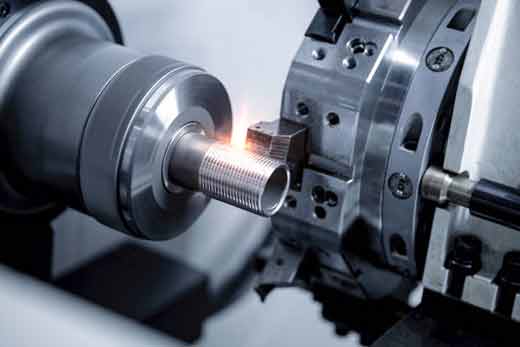

A CNC tooling machine is a computerized device that precisely cuts tiny bits of material off workpieces. CNC software is used to program the tooling for the specific position and angles of the workpiece. CNC machinery does not have computer vision; it relies on coordinates to guide itself through the process. Its axes are called X, Y, and Z, which are similar to X, Y, and Z in math.